- Phone/Text: +8615138484554

- Email: [email protected]

-

It can be independent of the construction site and is suitable for small and medium-sized projects.

Are you looking for high-performance concrete pump trucks that deliver faster pouring, lower fuel costs, and unmatched reliability? At SMAT Machinery, we engineer cutting-edge pump trucks designed to maximize productivity on any job site—from high-rise buildings to infrastructure projects. SMAT has standard concrete boom pump truck, concrete pump with mixer machine, mixer truck with boom pump. various options for your project.

Concrete Boom Truck

Chassis Model: Howo/Dongfeng/Shacman/Sinotruck

Boom reach: 28-63 meters

360° full rotation capability

Concrete Boom Pump with Mixer

Integrated twin-shaft mixer (capacity: 6-9 m³)

Simultaneous mixing and pumping

Ideal for remote sites with limited concrete supply

Mixer Truck with Boom Pump

8-12 m³ transit mixer + boom pump

Continuous operation capability

Reduced equipment footprint on site

| FULL LENGTH | 9400mm | 8200mm | 10500mm | 10450mm | 12600mm | 13850mm |

| TOTAL HEIGHT | 3300mm | 3260mm | 3360mm | 3800mm | 3950mm | 4000mm |

| TOTALWIDTH | 2450mm | 2350mm | 2500mm | 2500mm | 2550mm | 2550mm |

| SELF WEIGHT | 16000Kg | 17000Kg | 26000Kg | 23000Kg | 35000Kg | 44000Kg |

| BOOM VERTICAL HEIGHT | 21.9m | 26m | 38m | 40m | 50m | 62.5m |

| BOOM HORIZONTAL REACH | 18.1m | 21.6m | 33.5m | 36.2m | 46m | 58.5m |

| BOOM VERTICAL DEPTH | 8m | 10.5m | 22m | 24.5m | 36.5m | 47m |

| BOOM FOLDING | 3Z | 5RZ | 5RZ | 5RZ | 6RZ | 6RZ |

| EACH ARM LENGTH | 7100mm/6100mm/4900mm | 5500mm/4100mm/3900mm/3900mm/4300mm | 7500mm/6200mm/6100mm/6700mm/6700mm | 8100mm/6600mm/6000mm/7200mm/7600mm | 10000mm/8250mm/8050mm/9450mm/5750mm/4300mm | 11500mm/9030mm/9300mm/10270mm/11030mm/7500mm |

| EACH ARM CORNER ANGLE | 90°/180°/180° | 90°/180°/180°/212°/180° | 90°/180°/180°/230°/212° | 90°/180°/180°/207°/211° | 90°/180°/180°/243°/220°/110° | 90°/180°/180°/230°/180°/180° |

| END HOSE LENGTH | 3m | 3m | 3m | 3m | 3m | 3m |

| TURNTABLE ROTATIONANGLE | ±360° | ±360° | ±360° | ±360° | ±360° | ±360° |

| FRONT OUTRIGGER WIDTH | 4850mm | 5130mm | 6800mm | 8100mm | 9500mm | 12870mm |

| REAROUTRIGGERWIDTH | 3300mm | 5000mm | 8350mm | 9000mm | 9800mm | 12245mm |

| LONGITUDINAL DISTANCE OF FRONT AND REAR LEGS | 5200mm | 5100mm | 6800mm | 7400mm | 10400mm | 12347mm |

The parts used in SMAT concrete pumps are all top brands. Only by strictly demanding every part and link, SMAT can deliver the most satisfactory machine to customers.

Designed basedon accurate datasupport,strictcheckingofraw materials andwelding process. The multi-section articulated boom delivers concrete to precise locations. Made of high-strength steel, it offers flexibility and reach (up to 60+ meters), controlled via remote for accurate placement.

01

Stabilizing legs extend hydraulically to balance the truck during operation. They prevent tipping and ensure safety, especially when the boom is fully extended.

02

The heavy-duty chassis supports the entire system. Designed for mobility, it integrates the engine, cabin, and pumping components for on-site maneuverability. Various chassis brand optional for your requirement.

03

The pump pipeline is a composite double. layer wearresistantconveying pipe,with the wear-resistantdegree reaching to 50000 cubic meters. Steel or rubber pipes transport concrete from the pump to the boom end. Sections are connected with quick-release clamps for easy assembly and cleaning.

04

Adopt German HBC controller to realize faultself-detection. Display alarm, solve problems quickly. Adopt modular design and easy installation. It can be customized according to engineering needs to improve the adaptability and flexibility of the equipment.In case machine parts fail, regional debugging can be used to solve the problem and avoid time costs.

05

Latest design of internal structure, optimized the pump efficiency. Non-stick, easy clean. The receiving container stores fresh concrete before pumping. Agitators inside prevent segregation and ensure mix consistency during transfer.

06

Hydraulic hosejoint offamousbrand, ensure the safety of hydraulicsystem and no leakage.

07

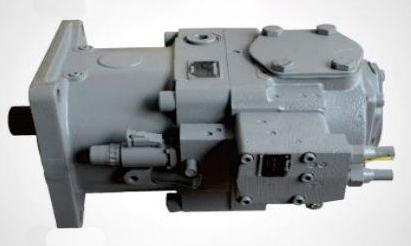

Adopts Rexroth toensure the reliable operation system,reduces pump time and maintenance cost.Protect the dieselengine.

08

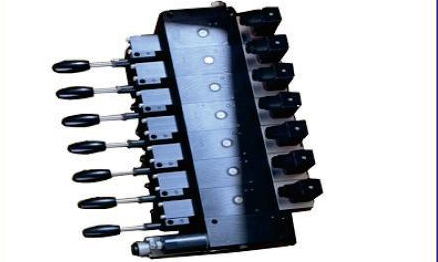

Application of the electronic proportional control valve improves working efficiency through minimizing boom rolling and enlarge the flexibility of the boom andoutrigger functions at the same time.

09

lmported transfer case, reduce waste during system running.

10

SMAT provides varies concrete machines for your project.